#Compressor Valve Plates

Explore tagged Tumblr posts

Text

Best Compressor Valve Plates In India

Enhance compressor performance with Indian Trade Bird's compressor valve plates. Our platform connects you with trusted suppliers offering high-quality valve plates designed to optimize airflow and increase efficiency in compressor systems.

Valve plates play a crucial role in regulating air intake and exhaust in compressors, ensuring smooth operation and maximum performance. Whether you're in the automotive, manufacturing, or construction industry, our diverse range of valve plates caters to various compressor models and applications. Indian Trade Bird simplifies the procurement process, offering competitive pricing and timely delivery to keep your compressor systems running smoothly. With our platform, you gain access to a wide network of reputable suppliers known for their reliability and commitment to quality.

0 notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

Danfoss: Engineering Precision for Marine and Industrial Efficiency Explore Top Products at Aeliya Marine Tech

In demanding fields such as marine engineering, offshore drilling, HVAC, and industrial automation, there is no place for equipment malfunction. Systems need to perform flawlessly, optimally, and under harsh conditions. Step forward Danfoss, a world leader in energy-efficient, precision-engineered components utilized across industries from shipping to manufacturing.

At Aeliya Marine Tech, we’re committed to showcasing a wide range of authentic Danfoss products, specifically designed for maintenance engineers, procurement departments, and system integrators who require quality, availability, and technical support. From pressure switches to thermostatic valves, transmitters, or frequency converters, our catalog provides reliable Danfoss solutions at your doorstep.

About Danfoss: Global Excellence with Local Impact

Established in Denmark in 1933, Danfoss Group is now one of the most renowned industrial technology names. Famous for its energy and climate solutions, Danfoss has been transforming the way mechanical and electrical systems function.

Their products cater to:

Shipboard air-conditioning and HVAC equipment

Hydro power and motor control

Refrigeration and temperature control

Automation and sensor monitoring

Regulation of pressure and flow in pipes

With a strong focus on sustainability, innovation, and robust engineering, Danfoss components are built to withstand high loads, variable environmental conditions, and demanding operating pressures perfect for marine and heavy industry applications.

Discover the Danfoss Product Range at Aeliya Marine

Aeliya Marine carries a large inventory of new and used Danfoss components. Below is a sampling of top product categories:

Danfoss Pressure Switches

Danfoss pressure switches are intended to control and monitor pressure in liquid and gaseous systems. These are widely applied in:

Compressor units

Boiler plants

Marine hydraulic systems

Characteristics:

Adjustable pressure range

Snap-action contacts

Gold-plated or silver-nickel contact options

IP65 enclosure for marine resistance

Some of the most popular models are the KP, RT, and MBC series each providing reliable protection and control for sophisticated systems.

2. Thermostatic Expansion Valves

Used in air-conditioning and refrigeration systems, Danfoss TXVs (Thermostatic Expansion Valves) control the injection of refrigerant. These valves are:

Compatible with several refrigerants (R134a, R404A, etc.)

Made of stainless steel or corrosion-resistant brass

Accurate in controlling superheat

They’re an essential part for vessels, cold storage units, HVAC systems, and industrial chillers.

3. Temperature and Pressure Transmitters

Danfoss offers robust transmitters that convert temperature or pressure changes into electrical signals. These are used for real-time monitoring and remote control.

Common applications:

Oil pressure regulation in marine engines

Boiler monitoring

Pump and compressor management

Models like MBS 3000 and AKS 32R provide fast response times, long lifecycle, and reliable output even in vibrating or corrosive environments.

4. Solenoid Valves

Whether it is flow control in a hydraulic circuit or fuel line control in an engine, Danfoss solenoid valves are designed for high-performance flow control.

Why select Danfoss solenoid valves?

Direct and servo-operated types

Broad voltage range support (AC/DC)

Compatible with ammonia and fluorinated refrigerants

Resistant to internal deposits and scaling

Standard variants include EVR series valves, employed in marine refrigeration as well as factory automation systems.

5. Electronic Controllers

For smarter automation and energy optimization, Danfoss offers a range of controllers for temperature, defrost, fan speed, and pressure setting. These products frequently feature:

Digital inputs and relay outputs

Simple-to-use displays

Remote programming and networking

EKC and ERC series controllers are great for food processing, cold chain logistics, and onboard climate control.

6. Variable Frequency Drives (VFDs)

Danfoss drives such as the VLT® series are high-end motor controllers that enhance energy efficiency and accuracy in pump, fan, and compressor systems.

Key advantages:

Up to 50% energy savings

Harmonic reduction

Integrated PID controllers

Marine-class certified versions (for offshore platforms)

These VFDs are essential for water treatment, engine room, and HVAC applications.

Industries and Applications

Danfoss products are internationally acclaimed for their extensive range of applications. Following are some of the most important industries that gain advantages from these products:

1. Marine & Offshore:

Ballast water control

HVAC and refrigeration of cabins & engine rooms

Desalination plant control

Hydraulic steering

2. Industrial Automation:

Assembly line equipment

Hydraulic presses

Industrial cooling

Motor speed control

3. Refrigeration & Cooling:

Cold storage plants

Walk-in freezers

Pharmaceutical storage

Cargo refrigeration for shipping containers

4. HVAC Systems:

Building climate control

Marine and oil rig cooling

Ventilation for factories and warehouses

Why Purchase Danfoss from Aeliya Marine Tech?

Buying can be a hassle particularly when time is of the essence, documentation is scarce, or parts are outdated. That’s where Aeliya Marine comes in.

Only Genuine Danfoss Parts

We only offer genuine Danfoss products thoroughly inspected, tested (if used), and supported by documentation where possible.

Photos and Detailed Listings

Every product listing features:

Model numbers

Technical specifications

High-quality photos

Condition tags (New, Used, Refurbished)

This provides clarity before you purchase.

1. Global Shipping from Mumbai

Our Mumbai-based centralized warehouse manages same-day or next-day shipments and accommodates international courier partners for secure, fast delivery.

2. Assistance from Actual Engineers

Stuck on model identification or looking for a compatible substitute? Our internal staff assists all questions with extensive product knowledge.

3. Value & Affordability

We provide competitive pricing on new, used, and surplus items perfect for cost-conscious repairs and replacements.

4. Sample Listings You May Find Today

Following are just a few examples of available or recently added Danfoss components at Aeliya Marine:

Danfoss KP35 Pressure Switch 060–110691

Danfoss RT 116 Pressure Switch 017–521566

Danfoss MBS 3000 Pressure Transmitter

Danfoss TX2 Thermostatic Valve

Danfoss VLT2800 Frequency Drive

Danfoss EV220B Solenoid Valve

Our inventory turns over frequently, so if you don’t find what you’re looking for ask us. We might have it on hand offline.

Aeliya Marine: Your Partner for Legacy and Modern Systems

Most vessels and factories blend legacy systems with newer upgrades. Sourcing replacement parts can be problematic particularly when OEMs end production of models. That’s where Aeliya Marine is an expert:

Finding equivalent models

Recommending drop-in substitutes

Providing hard-to-find parts

Together with Danfoss’ product compatibility promise and our multi-brand sourcing knowledge, your operations remain up and running with the minimum loss of time.

Get Your Systems Running with the Best of Danfoss

In any mission-critical application marine, manufacturing, or HVAC your components are as good as the brand that backs them. With Danfoss, you’re investing in precision engineering, energy efficiency, and operational safety. And with Aeliya Marine Tech, you’re supported by a supplier who gets your sense of urgency, answers your questions, and delivers worldwide.

More Products explore

Click Here To View the Complete Danfoss Products Collection.

#industrial equipment#automation#industrialautomation#industrial spare parts#industrial and marine automation#marine automation#industrial automation#pcb#amplifier#meter#danfoss#marineautomation#automationmarine#automationparts#marineparts#marineautomationparts#automationmarineparts#brand#products

0 notes

Text

Check Valve Buying Guide: 1 Inch Valve, Price in India, and Application by Type

Check Valve Buying Guide: 1 Inch Valve, Price in India, and Application by Type

Choosing the right 1-inch check valve can save you from costly breakdowns and system failures. This buying guide covers check valve types, uses, 2025 price insights, and tips to choose the right one for your industry.

What is a 1 Inch Check Valve?

A 1-inch check valve is a one-way valve designed for pipelines with a 1-inch diameter. It prevents backflow and protects pumps and compressors.

✅ Key Features:

One-direction flow control

No manual operation required

Available in swing, lift, ball, NRV, and wafer types

Types of 1 Inch Check Valves & Their Applications

1. Swing Check Valve

Has a hinged disc

Best for horizontal installations

✅ Applications: Water pipelines, drainage, fire protection ✅ Materials: Cast Iron, Stainless Steel

2. Lift Check Valve

Disc lifts vertically with pressure

Ideal for clean fluid systems

✅ Applications: Steam lines, hot water systems ✅ Materials: SS304, Bronze

3. Ball Check Valve

Uses a rubber/SS ball

Works well with thick or dirty fluids

✅ Applications: Chemical drains, slurry lines ✅ Materials: PVC, PP, SS

4. Wafer (Dual Plate) Check Valve

Spring-loaded plates

Space-saving, light design

✅ Applications: HVAC, marine pipelines ✅ Materials: SS316, Carbon Steel

5. NRV (Non-Return Valve)

Generic term for one-way valves

Covers multiple types

✅ Applications: Water motors, irrigation, submersible pumps ✅ Materials: Brass, SS, PVC

Price of 1 Inch Check Valves in India (2025)

💡 Prices vary based on material, pressure rating, and brand.

Valve TypeMaterialPrice Range (INR)Swing Check ValveCast Iron₹250 – ₹500Lift Check ValveStainless Steel₹350 – ₹850Ball Check ValvePP / PVC / SS₹180 – ₹600Wafer Check ValveSS304 / 316₹900 – ₹1,500Brass NRVBrass₹200 – ₹450Air Check ValveSS / Brass₹300 – ₹750Hydraulic NRVForged Steel₹500 – ₹1,200

How to Choose the Right 1 Inch Valve?

🔍 Buyer Checklist:

Application – Water, air, chemical, or hydraulic?

Flow direction – Horizontal or vertical?

System pressure – Low, medium, or high?

Material compatibility – Match with fluid type

Installation space – Limited or spacious setup?

Industrial Use Cases (Udyog Wise)

Industry Preferred Valve Type Reason Agriculture NRV, Brass Swing Valve Cost-effective, reliable Construction Swing & Lift Valve Heavy-duty applications HVAC Wafer Check Valve Space-saving, light Chemicals Ball Check Valve (PP/SS)Handles impurities Hydraulic Systems Hydraulic NRV High-pressure performance Domestic Pumps Brass or PVC NRV Affordable, corrosion-proof

FAQs

Q1. What is the price of a 1-inch NRV valve in India?

A 1-inch NRV valve in India costs between ₹200 to ₹450 depending on material like brass or PVC.

Q2. Which check valve is best for water motors?

Brass NRV or swing check valves are ideal for water motors due to durability and smooth flow control.

Q3. Can I use a lift check valve for vertical piping?

Yes, lift check valves are ideal for vertical piping where upward flow is needed with clean fluids.

Q4. Is there a difference between a check valve and NRV?

No major difference. “NRV” is the Indian term for a check valve; both function the same way.

Q5.How long does a 1-inch check valve last?

With proper material and installation, it can last 5–10 years depending on the fluid and pressure.

0 notes

Text

NRV Type Guide: Best Non Return Valves by Udhhyog

🛠️ All About Non Return Valves (NRV): Types, Functions & Supply – From Udhhyog

In industrial piping systems, the non return valve (NRV) is one of the most vital components. Whether it's water, gas, or chemicals, a non return setup ensures that media flows in only one direction—protecting pumps, preventing contamination, and ensuring safety.

At Udhhyog, we are proud to be one of India’s leading suppliers of industrial NRVs. We supply to a wide network across Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and beyond.

In this guide, we’ll explain how non return valves and check valves work, explore NRV types, and help you choose the right solution for your industrial application.

🔍 What is a Non Return Valve?

A non return valve, commonly abbreviated as NRV, is a one-way valve that allows media to flow in a single direction only. Its function is simple yet crucial—it prevents backflow.

Backflow can cause serious problems such as:

Damage to pumps or compressors

Contamination of clean fluid systems

Pressure surges or water hammer effects

This is why every industry from water treatment to oil & gas relies on NRV non return valves.

💡 Non Return Valve and Check Valve – What’s the Difference?

The terms non return valve and check valve are often used interchangeably, and while they serve the same purpose (preventing reverse flow), there are slight differences in design and use.

Non Return Valve (NRV): Typically used in domestic water supply, low-pressure pipelines, or irrigation.

Check Valve: Often used in industrial, chemical, or high-pressure applications.

At Udhhyog, we stock both variants—helping clients across industries choose the right fit based on pressure, media, and installation style.

🧩 NRV Type – Explained

There are multiple NRV types, each suited for different applications. Here are the most common:

1. Swing Type Non Return Valve

This NRV type has a disc that swings open when fluid flows forward and closes with reverse flow pressure.

Applications: Water pipelines, fire protection systems

Benefits: Simple design, low maintenance

2. Lift Type NRV

The internal disc lifts when fluid pressure increases and drops back to seal when flow reverses.

Applications: Steam lines, boilers

Benefits: Tight seal, reliable for vertical flows

3. Ball Type Non Return Valve

This design uses a rubber or metal ball that rolls back to seal off reverse flow.

Applications: Slurry, sewage, chemical industries

Benefits: Self-cleaning, good for dirty liquids

4. Wafer Type Check Valve (Dual Plate)

A compact, flange-mounted design using two spring-loaded plates. One of the best NRV types for space-saving setups.

Applications: HVAC systems, power plants

Benefits: Low pressure drop, compact, corrosion-resistant

🏭 Industries That Use NRV Non Return Valves

Udhhyog supplies valves to a variety of sectors that depend heavily on non return technology:

Water Treatment Plants

Chemical Processing Units

Pharmaceutical Manufacturing

Oil and Gas Refineries

Firefighting Systems

Irrigation and Agriculture

In each of these sectors, a failure in flow control could cause severe safety hazards. This is why the reliability of non return valve and check valve systems is paramount.

🌐 Udhhyog – India’s Trusted Valve Supplier

We at Udhhyog are more than just a supplier—we are a partner in your industry’s growth. Our valves are trusted by engineers, contractors, and project heads across India.

Why Udhhyog?

✔ Pan-India Supply – We are suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh

✔ Huge Inventory – All NRV types available in MS, SS, CI, WCB & more

✔ Fast Dispatch – Orders shipped within 1-2 working days

✔ Credit Facility – Flexible credit for loyal buyers

✔ Technical Expertise – Our experts help you choose the right NRV for your project

Explore our full product catalog: 👉 https://udhhyog.com/valves

🔧 Installation Tips for Non Return Valves

Correct installation ensures long-lasting performance of your NRV non return valve:

✅ Always match the valve size with pipeline diameter

✅ Ensure the flow arrow aligns with your system's direction

✅ Use proper gaskets between flanges

✅ Avoid overtightening to prevent cracking

✅ For vertical installations, use lift-type or ball-type NRVs

A poorly installed non return setup can lead to leakage, water hammer, or pressure failure.

📊 NRV Type Comparison Table

NRV TypeIdeal ApplicationFlow DirectionMaintenanceCostSwing NRVWater, fire systemsHorizontalLowModerateLift NRVSteam, vertical systemsVerticalModerateLowBall NRVSewage, slurryAnySelf-cleaningModerateWafer Type (Dual Plate)HVAC, compact setupsAnyLowAffordable

🔍 What to Consider When Choosing an NRV Non Return Valve?

Media Type: Water, chemicals, slurry, steam

Operating Pressure and Temperature

Pipeline Orientation: Horizontal or vertical

Maintenance Access

Material of Construction: SS304, SS316, CI, MS, etc.

Udhhyog’s team helps industries select the best fit based on detailed specs and flow conditions.

🔄 Benefits of Using Non Return Valve and Check Valve in Your Systems

✅ Prevent backflow damage

✅ Protect pumps and compressors

✅ Prevent contamination in water systems

✅ Reduce water hammer in high-speed flows

✅ Enable automated, maintenance-free operations

With thousands of installations completed across North India, Udhhyog valves are built to last and tested under strict quality control.

🧰 Other Valves Supplied by Udhhyog

In addition to NRVs, we also supply:

Ball Valves

Butterfly Valves

Gate Valves

Foot Valves

Y-Strainers

Explore our complete valve range: 👉 https://udhhyog.com/valves

🔚 Conclusion

Whether you're an engineer designing a water treatment system or a procurement head in the oil & gas sector, investing in the right non return valve and check valve is non-negotiable.

From swing type NRVs to dual plate wafer valves, Udhhyog has every NRV type your system could require—backed by quality, speed, and unmatched service.

🟢 Get in touch with us today to place your order or request a custom valve solution. We’re ready to power your flow with confidence.

#NonReturnValve#NRVType#NRVNonReturnValve#IndustrialValvesIndia#CheckValveIndia#FlowControlSolutions#Udhhyog#DelhiValveSupplier#BackflowPrevention#PipelineProtection

1 note

·

View note

Text

NRV Type Guide: Best Non Return Valves by Udhhyog

🛠️ All About Non Return Valves (NRV): Types, Functions & Supply – From Udhhyog

In industrial piping systems, the non return valve (NRV) is one of the most vital components. Whether it's water, gas, or chemicals, a non return setup ensures that media flows in only one direction—protecting pumps, preventing contamination, and ensuring safety.

At Udhhyog, we are proud to be one of India’s leading suppliers of industrial NRVs. We supply to a wide network across Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and beyond.

In this guide, we’ll explain how non return valves and check valves work, explore NRV types, and help you choose the right solution for your industrial application.

🔍 What is a Non Return Valve?

A non return valve, commonly abbreviated as NRV, is a one-way valve that allows media to flow in a single direction only. Its function is simple yet crucial—it prevents backflow.

Backflow can cause serious problems such as:

Damage to pumps or compressors

Contamination of clean fluid systems

Pressure surges or water hammer effects

This is why every industry from water treatment to oil & gas relies on NRV non return valves.

💡 Non Return Valve and Check Valve – What’s the Difference?

The terms non return valve and check valve are often used interchangeably, and while they serve the same purpose (preventing reverse flow), there are slight differences in design and use.

Non Return Valve (NRV): Typically used in domestic water supply, low-pressure pipelines, or irrigation.

Check Valve: Often used in industrial, chemical, or high-pressure applications.

At Udhhyog, we stock both variants—helping clients across industries choose the right fit based on pressure, media, and installation style.

🧩 NRV Type – Explained

There are multiple NRV types, each suited for different applications. Here are the most common:

1. Swing Type Non Return Valve

This NRV type has a disc that swings open when fluid flows forward and closes with reverse flow pressure.

Applications: Water pipelines, fire protection systems

Benefits: Simple design, low maintenance

2. Lift Type NRV

The internal disc lifts when fluid pressure increases and drops back to seal when flow reverses.

Applications: Steam lines, boilers

Benefits: Tight seal, reliable for vertical flows

3. Ball Type Non Return Valve

This design uses a rubber or metal ball that rolls back to seal off reverse flow.

Applications: Slurry, sewage, chemical industries

Benefits: Self-cleaning, good for dirty liquids

4. Wafer Type Check Valve (Dual Plate)

A compact, flange-mounted design using two spring-loaded plates. One of the best NRV types for space-saving setups.

Applications: HVAC systems, power plants

Benefits: Low pressure drop, compact, corrosion-resistant

🏭 Industries That Use NRV Non Return Valves

Udhhyog supplies valves to a variety of sectors that depend heavily on non return technology:

Water Treatment Plants

Chemical Processing Units

Pharmaceutical Manufacturing

Oil and Gas Refineries

Firefighting Systems

Irrigation and Agriculture

In each of these sectors, a failure in flow control could cause severe safety hazards. This is why the reliability of non return valve and check valve systems is paramount.

🌐 Udhhyog – India’s Trusted Valve Supplier

We at Udhhyog are more than just a supplier—we are a partner in your industry’s growth. Our valves are trusted by engineers, contractors, and project heads across India.

Why Udhhyog?

✔ Pan-India Supply – We are suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh

✔ Huge Inventory – All NRV types available in MS, SS, CI, WCB & more

✔ Fast Dispatch – Orders shipped within 1-2 working days

✔ Credit Facility – Flexible credit for loyal buyers

✔ Technical Expertise – Our experts help you choose the right NRV for your project

Explore our full product catalog: 👉 https://udhhyog.com/valves

🔧 Installation Tips for Non Return Valves

Correct installation ensures long-lasting performance of your NRV non return valve:

✅ Always match the valve size with pipeline diameter

✅ Ensure the flow arrow aligns with your system's direction

✅ Use proper gaskets between flanges

✅ Avoid overtightening to prevent cracking

✅ For vertical installations, use lift-type or ball-type NRVs

A poorly installed non return setup can lead to leakage, water hammer, or pressure failure.

📊 NRV Type Comparison Table

NRV TypeIdeal ApplicationFlow DirectionMaintenanceCostSwing NRVWater, fire systemsHorizontalLowModerateLift NRVSteam, vertical systemsVerticalModerateLowBall NRVSewage, slurryAnySelf-cleaningModerateWafer Type (Dual Plate)HVAC, compact setupsAnyLowAffordable

🔍 What to Consider When Choosing an NRV Non Return Valve?

Media Type: Water, chemicals, slurry, steam

Operating Pressure and Temperature

Pipeline Orientation: Horizontal or vertical

Maintenance Access

Material of Construction: SS304, SS316, CI, MS, etc.

Udhhyog’s team helps industries select the best fit based on detailed specs and flow conditions.

🔄 Benefits of Using Non Return Valve and Check Valve in Your Systems

✅ Prevent backflow damage

✅ Protect pumps and compressors

✅ Prevent contamination in water systems

✅ Reduce water hammer in high-speed flows

✅ Enable automated, maintenance-free operations

With thousands of installations completed across North India, Udhhyog valves are built to last and tested under strict quality control.

🧰 Other Valves Supplied by Udhhyog

In addition to NRVs, we also supply:

Ball Valves

Butterfly Valves

Gate Valves

Foot Valves

Y-Strainers

Explore our complete valve range: 👉 https://udhhyog.com/valves

🔚 Conclusion

Whether you're an engineer designing a water treatment system or a procurement head in the oil & gas sector, investing in the right non return valve and check valve is non-negotiable.

From swing type NRVs to dual plate wafer valves, Udhhyog has every NRV type your system could require—backed by quality, speed, and unmatched service.

🟢 Get in touch with us today to place your order or request a custom valve solution. We’re ready to power your flow with confidence.

#NonReturnValve#NRVType#NRVNonReturnValve#IndustrialValvesIndia#CheckValveIndia#FlowControlSolutions#Udhhyog#DelhiValveSupplier#BackflowPrevention#PipelineProtection

1 note

·

View note

Text

NRV Type Guide: Best Non Return Valves by Udhhyog

🛠️ All About Non Return Valves (NRV): Types, Functions & Supply – From Udhhyog

In industrial piping systems, the non return valve (NRV) is one of the most vital components. Whether it's water, gas, or chemicals, a non return setup ensures that media flows in only one direction—protecting pumps, preventing contamination, and ensuring safety.

At Udhhyog, we are proud to be one of India’s leading suppliers of industrial NRVs. We supply to a wide network across Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh, and beyond.

In this guide, we’ll explain how non return valves and check valves work, explore NRV types, and help you choose the right solution for your industrial application.

🔍 What is a Non Return Valve?

A non return valve, commonly abbreviated as NRV, is a one-way valve that allows media to flow in a single direction only. Its function is simple yet crucial—it prevents backflow.

Backflow can cause serious problems such as:

Damage to pumps or compressors

Contamination of clean fluid systems

Pressure surges or water hammer effects

This is why every industry from water treatment to oil & gas relies on NRV non return valves.

💡 Non Return Valve and Check Valve – What’s the Difference?

The terms non return valve and check valve are often used interchangeably, and while they serve the same purpose (preventing reverse flow), there are slight differences in design and use.

Non Return Valve (NRV): Typically used in domestic water supply, low-pressure pipelines, or irrigation.

Check Valve: Often used in industrial, chemical, or high-pressure applications.

At Udhhyog, we stock both variants—helping clients across industries choose the right fit based on pressure, media, and installation style.

🧩 NRV Type – Explained

There are multiple NRV types, each suited for different applications. Here are the most common:

1. Swing Type Non Return Valve

This NRV type has a disc that swings open when fluid flows forward and closes with reverse flow pressure.

Applications: Water pipelines, fire protection systems

Benefits: Simple design, low maintenance

2. Lift Type NRV

The internal disc lifts when fluid pressure increases and drops back to seal when flow reverses.

Applications: Steam lines, boilers

Benefits: Tight seal, reliable for vertical flows

3. Ball Type Non Return Valve

This design uses a rubber or metal ball that rolls back to seal off reverse flow.

Applications: Slurry, sewage, chemical industries

Benefits: Self-cleaning, good for dirty liquids

4. Wafer Type Check Valve (Dual Plate)

A compact, flange-mounted design using two spring-loaded plates. One of the best NRV types for space-saving setups.

Applications: HVAC systems, power plants

Benefits: Low pressure drop, compact, corrosion-resistant

🏭 Industries That Use NRV Non Return Valves

Udhhyog supplies valves to a variety of sectors that depend heavily on non return technology:

Water Treatment Plants

Chemical Processing Units

Pharmaceutical Manufacturing

Oil and Gas Refineries

Firefighting Systems

Irrigation and Agriculture

In each of these sectors, a failure in flow control could cause severe safety hazards. This is why the reliability of non return valve and check valve systems is paramount.

🌐 Udhhyog – India’s Trusted Valve Supplier

We at Udhhyog are more than just a supplier—we are a partner in your industry’s growth. Our valves are trusted by engineers, contractors, and project heads across India.

Why Udhhyog?

✔ Pan-India Supply – We are suppliers in Delhi, Punjab, Gujarat, Rajasthan, Jammu & Kashmir, Himachal Pradesh, Uttar Pradesh

✔ Huge Inventory – All NRV types available in MS, SS, CI, WCB & more

✔ Fast Dispatch – Orders shipped within 1-2 working days

✔ Credit Facility – Flexible credit for loyal buyers

✔ Technical Expertise – Our experts help you choose the right NRV for your project

Explore our full product catalog: 👉 https://udhhyog.com/valves

🔧 Installation Tips for Non Return Valves

Correct installation ensures long-lasting performance of your NRV non return valve:

✅ Always match the valve size with pipeline diameter

✅ Ensure the flow arrow aligns with your system's direction

✅ Use proper gaskets between flanges

✅ Avoid overtightening to prevent cracking

✅ For vertical installations, use lift-type or ball-type NRVs

A poorly installed non return setup can lead to leakage, water hammer, or pressure failure.

📊 NRV Type Comparison Table

NRV TypeIdeal ApplicationFlow DirectionMaintenanceCostSwing NRVWater, fire systemsHorizontalLowModerateLift NRVSteam, vertical systemsVerticalModerateLowBall NRVSewage, slurryAnySelf-cleaningModerateWafer Type (Dual Plate)HVAC, compact setupsAnyLowAffordable

🔍 What to Consider When Choosing an NRV Non Return Valve?

Media Type: Water, chemicals, slurry, steam

Operating Pressure and Temperature

Pipeline Orientation: Horizontal or vertical

Maintenance Access

Material of Construction: SS304, SS316, CI, MS, etc.

Udhhyog’s team helps industries select the best fit based on detailed specs and flow conditions.

🔄 Benefits of Using Non Return Valve and Check Valve in Your Systems

✅ Prevent backflow damage

✅ Protect pumps and compressors

✅ Prevent contamination in water systems

✅ Reduce water hammer in high-speed flows

✅ Enable automated, maintenance-free operations

With thousands of installations completed across North India, Udhhyog valves are built to last and tested under strict quality control.

🧰 Other Valves Supplied by Udhhyog

In addition to NRVs, we also supply:

Ball Valves

Butterfly Valves

Gate Valves

Foot Valves

Y-Strainers

Explore our complete valve range: 👉 https://udhhyog.com/valves

🔚 Conclusion

Whether you're an engineer designing a water treatment system or a procurement head in the oil & gas sector, investing in the right non return valve and check valve is non-negotiable.

From swing type NRVs to dual plate wafer valves, Udhhyog has every NRV type your system could require—backed by quality, speed, and unmatched service.

🟢 Get in touch with us today to place your order or request a custom valve solution. We’re ready to power your flow with confidence.

#NonReturnValve#NRVType#NRVNonReturnValve#IndustrialValvesIndia#CheckValveIndia#FlowControlSolutions#Udhhyog#DelhiValveSupplier#BackflowPrevention#PipelineProtection

0 notes

Text

Understanding Pneumatic Actuators: Working Principles, Types, And Key Components Explained

Pneumatic actuators are essential components in modern industrial automation and machinery. They convert compressed air energy into mechanical motion, enabling precise control of valves, grippers, and other mechanical systems. Widely used in manufacturing, robotics, and process industries, pneumatic actuators are valued for their reliability, simplicity, and cost-effectiveness. This article explores their working principles, common types, and key components.

1. Working Principles Of Pneumatic Actuators

Pneumatic actuators operate on the fundamental principle of pressure differential. When compressed air is introduced into the actuator, it creates a force that moves internal components, generating linear or rotary motion. Here’s a step-by-step breakdown:

Air Supply: Compressed air (typically 4–7 bar or 60–100 psi) is supplied from a pneumatic system or compressor.

Pressure Application: Air enters the actuator’s chamber, exerting pressure on a piston, diaphragm, or vane.

Motion Generation: The pressure differential across the piston/diaphragm creates linear or rotational movement.

Return Mechanism: In single-acting actuators, a spring returns the piston to its original position when air pressure is released. Double-acting actuators use compressed air to move in both directions.

Key advantages include rapid response times, high force-to-size ratios, and suitability for hazardous environments (no sparks or overheating).

2. Types Of Pneumatic Actuators

Pneumatic actuators are categorized based on their motion type and design:

A. Linear Actuators

Single-Acting: Compressed air moves the piston in one direction; a spring returns it. Ideal for simple on/off applications (e.g., clamping).

Double-Acting: Air pressure moves the piston in both directions, enabling precise bidirectional control. Common in industrial valves and automation.

B. Rotary Actuators

Rack-and-Pinion: A piston with a rack gear rotates a pinion gear, producing rotary motion. Used for quarter-turn valve control (e.g., ball valves).

Vane-Type: Compressed air pushes vanes in a circular chamber, generating torque. Suitable for continuous rotation applications.

Scotch Yoke: Converts linear piston motion into rotary motion via a slotted yoke mechanism. Offers high torque for heavy-duty valves.

C. Specialty Actuators

Diaphragm Actuators: Use a flexible diaphragm instead of a piston. Common in pressure control valves.

Rodless Actuators: Eliminate the piston rod, allowing for compact designs in confined spaces.

3. Key Components Of Pneumatic Actuators

Understanding the internal structure of pneumatic actuators is crucial for maintenance and selection:

Cylinder Body: Houses the piston and contains compressed air. Made of aluminum, stainless steel, or engineered plastics.

Piston: Converts air pressure into linear motion. Sealed with O-rings to prevent air leakage.

Piston Rod: Transmits motion to external mechanisms. Often chrome-plated for durability.

End Caps: Seal the cylinder and include ports for air inlet/outlet.

Seals and Gaskets: Ensure airtight operation. Common materials include nitrile rubber (NBR) or polytetrafluoroethylene (PTFE).

Spring (Single-Acting): Provides return force in single-acting designs.

Position Sensors (Optional): Detect piston position for feedback in automated systems.

4. Applications And Industry Use Cases

Pneumatic actuators are ubiquitous in industries requiring fast, reliable motion control:

Manufacturing: Operating conveyor belts, assembly line grippers.

Oil and Gas: Controlling pipeline valves in explosive environments.

Food and Beverage: Hygienic actuators for packaging and filling systems.

Automotive: Robotic welding and painting systems.

Conclusion

Pneumatic actuators remain a cornerstone of industrial automation due to their simplicity, safety, and adaptability. By leveraging compressed air, they provide efficient motion control for diverse applications. Engineers and technicians must consider factors like load requirements, operating environment, and cycle rates when selecting the right actuator type. As industries evolve, innovations in materials and smart pneumatics (e.g., IoT-enabled actuators) are enhancing their performance and integration with modern control systems.

This article provides a comprehensive overview of pneumatic actuators while maintaining readability for both technical and non-technical audiences.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

0 notes

Text

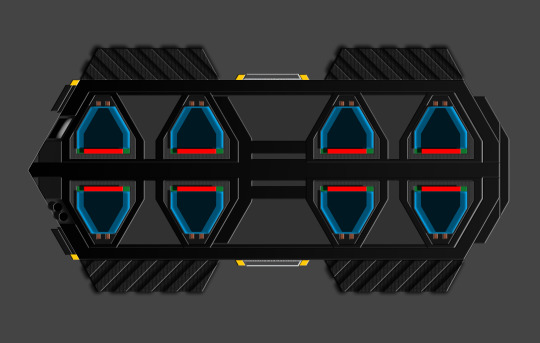

design notes: we are going to start with the cooling solution, well because that is the easiest to do, and also we have seen it before

so beneath these ceramic heat diffusion plates we have diffusion bonded cooling modules, and heats gets dissipated from the cells, through the modules, to the ceramic plates below the vehicle

as such, we can move on to the cells and how they are implemented, connected to compressed hydrogen tanks to start with

For laters

or not, we started small by rationalizing electric plots, they're different than the flat battery ones, less conceptual maybe, then we positioned H2 fuel cells, scaled at 80% of the containers, now what we have around them is part of the diffusion bonded modules so these take place also around the fuel cells

next we should see our different in out circuits take place, carve them in the rest of surrounding modules material mostly

below compressed hydrogen tanks we have H2 in and out, heat gets displaced below where we have oxygen in and water vapor/water out

tidy so far, we should have the fuel cell view and the bonded modules view, we already posted the 3rd and last one

Laters

ps. H2 fuel cells are very large, well it's a large truck, possibly they're organized horizontally and much less vertically, clockwise we have the different layers of it H2 transfer bank or H2 flow, anode, electrolyte layer, cathode, and 02 transfer bank or O2 flow

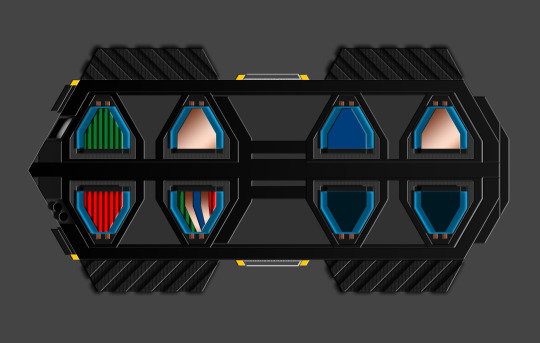

design notes continued: now if we sandwich those H2 cells between the diffusion bonded modules, implement the circuits on the sides, I didn't want to get out of those containers anyways, H2 in and out seem pretty straightforward, even water vapor/water out that's water for showers, sinks, and toilets, how do we get fresh air in there…

what comes first, the chicken or the egg, or the farmer, or the gasoline pump guy, or hydrocarbons in the gasoline, they look older even

design notes continued: we have proceeded by banks which is what I wanted to do for oxygen in, water vapor/water out, which is mostly water vapor from what I understand, for clarity we have H2 in out in green and oxygen in, water vapor/water out in red, superposed

we are not going to go into the piping on this slide but luckily above we have that motors deck midsection column where all of this can take place, including pumps for oxygen, water vapor/water in/out

why the pumps because we need flow and we have a huge asset to tap into, the refrigerating condenser, where on separate ducts water vapor can become condensed and resulting distilled water goes into the side water tanks

while it's not drinking grade from the source, depletes the body of electrolytes, it can be tapped into for everything else, and by dropping mineral tablets into the kitchenette 15/20l capacity water reservoir we obtain drinking grade water

and that in itself is a huge win for the autonomy of the vehicle, that it can procure sizeable amounts of water from H2 conversion, even drinking water

gone for a walk, still the most eco friendly way to move around

ps. yes, oxygen in should be connected to air intakes on the front of the vehicle, how that works with the pumps, well it should go through them for a pressurized cycle, basically we have not much use for it after water is in the tanks, pressure valves to the outside then

Laters

or that air pressure is useful for the water system I don't know those things, pressure valves would still be useful for the pressure inside the tanks not to exceed a certain figure

I have difficulty with how air from frontal air intakes is going to go through all of these cells… It has to be some of those special pumps that process anything you throw at them air, water vapor, water, or maybe I am wrong and it's compressors instead, at any rate air goes in the front and out from the pressure valves of the water tanks, water stays in the tanks

we could do the ducts next or maybe not, these ducts run inside the midsection column of the motors deck, since that column can be any height we set so everything can fit there, incl ducts for compressed H2 storage tanks cooling and the water in gray water out to where we need them and to the septic tank after that, very important that midsection column in the motors deck

also these don't look like a single set, maybe that's when it becomes too much asking, more like 2 sets along the lines of what we did H2 tanks cooling, 2 sets of ducts, 2 pumps or compressors

the point that I am pretty certain of is that separate ducts running inside that refrigerated condenser will produce distilled water from H2 conversion, it's a huge point maybe why it makes the rest less important, still is

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] ➡150 PSI Tyre Foot Operated Air Pump Heavy Steel Body Foot Pump ➡FEATURES ➡Heavy Steel Foot Pump ➡An air pump is an absolute necessity in our lives. ➡But often times we have to use different air pumps for inflating widely varying objects like footballs or tyres. ➡MATERIAL ➡Air Pump Compressor comes in Stainless Steel metal boot body With Ergonomically Cylinder Design, Faster Pumping Than Normal Barrel Pump, cylinder design, more air pressure, easy and effortless. ➡RATED VOLTAGE ➡DC 12 V Tyre Infiltrator →RATED PRESSURE/CURRENT : 150 PSI/12 A ➡UNIVERSAL USES ➡Can be used for car, bikes, bicycle .also used for basketball, football & The smart valve head is suitable for All vehicles. ➡CYLINDRICAL DIAMETER ➡30 mm →HOSE : 1.5 m of extension hose. ➡Multiple Functions ➡Ideal to cars, Tires, motorbikes, cycles, peddle bikes tires and ➡inflatable boats, Basketball, Footballs, air beds. ➡The brass adapter metal is included in the package used for bicycles Tyre Valve Product Description FOOT OPERATED AIR PUMP : This air pump does not require electricity but instead works like a cycle pump. It comes with a rubberized grip and features an analogue dial to indicate the pressure readings. HEAVY DUTY Durable iron construction allows this pump to inflate objects up to 150 PSI and ensures long term performance. AIR FOOT PUMP Heavy Compressor For Bike,Car,Cycles,& all other vehicles emergency use for this item. FOOT OPERATED AIR PUMP : This air pump does not require electricity but instead works like a cycle pump. It comes with a rubberized grip and features an analogue dial to indicate the pressure readings.. BLACK POWDER Coated Frame Heavy Steel Chrome Plated Body Cylinder One Mtr Duplon Naylon Braided Hose With Analoge Pressure Gauge Handy Device for Easy Air Filling. [ad_2]

0 notes

Text

Check Valve Manufacturer in Germany

Check Valve Manufacturer in Germany

Valvesonly Europe is the top Check Valve Manufacturer in Germany. Check valves are also known as non return valves as they allow fluids to flow in one direction only and prevent from reverse flow. They are widely used in the industry where backflow prevention is critical in the operation such as the chemical industry, water treatment plants.

How does check valve work?

Check valve work automatically, depending on the fluid pressure to open and close the valve. As the fluid moves in the specified direction, it pushes the valve disc or ball in the opposite direction, enabling passage through the seat. If the direction of the flow changes, the disc or ball is pushed against the seat, closing the valve and stopping reverse flow. They help to ensure pipelines, pumps, compressors, and other fluid systems function well by allowing fluids flow in one direction and blocking it in the opposite.

Types of check valve:

Swing check valve

Lift check valve

Dual plate check valve

Non slam swing check valve

Tilting disc check valve

Pressure seal check valve

Foot Check valve

Forged steel swing check valve

Where Check valve is used?

Check valves are design to stop fluids from reverse flow and allow them to flow in one direction they are used in a wide range of application where backflow prevention is critical such as:

Water treatment plants

Oil and gas industry

Power plants

Chemical Processing

Chemical production and manufacturing facilities

Petrochemical plants

Fire Protection Systems

Marine and aviation applications

Pulp and Paper

Mining and Minerals

Aerospace and Defense

As a top Check Valve Manufacturer in Germany our valve provide these advantage:

Reverse Flow prevention: They ensure that fluids flow in one direction and there is no reverse flow of fluids.

Safety: By preventing reverse flow they protect equipments from damage caused by them like, water hammer

Automatic operation: They work automatically whether reverse flow is detected and don't require any external power.

Durable: They have robust construction which makes them withstand harsh conditions and extend service life.

Enhances System Efficiency: They reduce the risk of system failure and sustains pressure, enhancing overall operational effectiveness.

Versatile: Foot valves are used in a wide range of applications including water treatment, oil and gas, and HVAC

Description:

Body Material- Cast Iron and Cast Steel (LF2, A216, WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F91), Duplex and Super duplex steel [F51, F53, F55] Forged Steel A105, A105N, F11, F22, F304, F316, F91] Alloy20, Hastelloy, ALBR.

Size- ½” – 80”

Class-150 – 2500; PN10 – PN-450

Ends-threaded, socket weld, butt weld, flanged, lug, wafer

Visit our website for more detail: https://www.valvesonlyeurope.com/product-category/check-valve/

0 notes

Text

Check Valve Types You Need to Know (Swing, Lift, NRV & More) with Pricing Guide

Check valves are automatic safety valves that allow one-way flow and prevent backflow in pipelines. This guide will explain the main types—swing, lift, ball, and NRV—along with their pricing and usage in different industrial systems.

H2: What is a Check Valve?

A check valve (non-return valve or NRV) is a mechanical valve that allows fluid (liquid or gas) to flow in only one direction. It operates automatically and closes when reverse flow is detected.

🔍 Key Features:

Prevents reverse flow

Protects pumps and piping

No manual operation needed

Types of Check Valves (With Applications)

. Swing Check Valve

Hinge-based disc swings open with forward flow

Closes by gravity when flow reverses

Ideal for horizontal pipelines

✅ Used In: Water supply, sewage, chemical systems

2. Lift Check Valve

Disc lifts vertically under pressure

Works only in vertical or horizontal flow (with upward pressure)

Excellent for high-pressure clean fluids

✅ Used In: Steam lines, boilers, water systems

3. Ball Check Valve

Spring-loaded ball mechanism

Opens with pressure and seals tightly during reverse flow

Minimal maintenance, compact design

✅ Used In: Slurries, chemical dosing, wastewater treatment

4. Dual Plate (Wafer) Check Valve

Two half-disc plates with springs

Lightweight and compact between flanges

Quick shut-off for reverse flow

✅ Used In: HVAC, petroleum, marine systems

5. Air Check Valve

Controls direction of airflow

Prevents back-pressure in pneumatic systems

Ensures system stability

✅ Used In: Compressors, air dryers, pneumatic tools

6. Hydraulic Check Valve

Designed for oil flow in hydraulic systems

Maintains line pressure

Allows controlled flow return

✅ Used In: Press machines, loaders, industrial lifts

7. Non-Return Valve (NRV)

Indian industry name for check valve

Available in all types: swing, lift, ball, etc.

Widely used in plumbing & water systems

Comparison Table of Check Valve Types

Valve Type Flow Direction Installation Ideal Use Maintenance Swing Valve Horizontal Easy Water, sewage Low Lift Valve Vertical Moderate Steam, high-pressure lines Medium Ball Valve Any Easy Wastewater, chemicals Low Wafer Valve Any Compact Fit HVAC, oil & gas Low Air Valve One-Way Air Simple Pneumatics Low Hydraulic Valve One-Way Oil Robust Heavy machinery Medium

Check Valve Pricing Guide (2025 India)

Type Size (Inch)Material Price Range (INR) Swing1" – 4"CI, MS₹250 – ₹1,500 Lift1" – 6"SS, CI₹400 – ₹3,000 Ball½" – 3"PP, HDPE ₹100 – ₹1,200 Dual Plate (Wafer)2" – 8"SS 304/316₹800 – ₹5,500 Air Valve¼" – 2"Brass, SS₹150 – ₹1,800 Hydraulic Valve¼" – 2"Steel₹350 – ₹2,800

💡 Prices depend on brand, pressure class, and application type.

Where Are Check Valves Used?

🔧 Industrial Applications:

Water pumps (borewell, domestic, irrigation)

Compressed air systems

Hydraulic machinery

RO plants and sewage lines

Chemical & pharma pipelines

1-Inch Check Valve – Popular Size

The 1-inch check valve is one of the most commonly used sizes across sectors.

✅ Best For:

Domestic water systems

Submersible pump lines

Irrigation pipes

Advantages of Using the Right Check Valve

Reduces risk of backflow

Increases pump life

Prevents water hammer

Improves system safety

FAQs

Q1. What is the best type of check valve?

Swing and lift check valves are most widely used due to reliability, while ball valves are best for slurry or chemical use.

Q2. What does NRV stand for?

NRV means Non-Return Valve, the Indian term for a check valve that blocks backflow.

Q3. How much does a 1-inch check valve cost?

A 1-inch check valve typically costs ₹250 to ₹500, depending on type and material.

Q4. Can I use a check valve for air?

Yes, air check valves are made of brass or stainless steel and used in pneumatic systems.

Q5.What is the function of a ball check valve?

It uses a ball and spring to control flow direction and is suitable for thick or viscous fluids.

0 notes

Text

Exploring the differences between flange and blind flange

1. The characteristics of the two are different

The normal name of blind flange is flange cover, and it is also called blind flange or closed pipe. This is a kind of flange without hole in the middle, which is mainly used for the front end of pipe seal. It is used for sealing port, and its function is the same as that of sealing head and pipe cover. The blind hole seal is a detachable sealing device, and the seal of the sealing head is not ready to be opened again.

There are many materials for making blind flange, such as carbon steel, alloy, stainless steel, plastic, etc. Different materials of blind flange performance is also different, plastic blind flange corrosion resistance is good, but the strength is poor, and stainless steel blind flange is relatively obvious advantage flange. In the system that needs to be completely separated, generally speaking, it is used as a certain means of isolation. The blind flange is a solid with handle. It is more convenient to use the blind flange when it is used in isolation system. In the flange connection, it is necessary to use bolts to fasten the flange. The flange shall be sealed with gasket or play a temporary role in the test. Flange is a common component in pipeline engineering. Generally, flanges are used in pairs, according to the connection mode. Flange is divided into threaded flange, welding flange and clamp flange.

2. The application of the two methods is different

(1) The application of flange is due to its good performance. Widely used in pipeline, chemical, health, petroleum, construction, fire and other basic engineering.

(2) In the piping strength test or sealing test, the blind plate in the original start-up preparation stage cannot be used together with the connecting equipment (such as turbine, compressor, gasifier, reactor, etc.). Blind plate must be set at the joint of equipment and piping. When the equipment stops, please set the blind plate on the stop valve.

0 notes

Text

Wafer Type Check Valve & Non Return Valve Types & Price – Udhhyog

A check valve, also known as a non return valve, is critical in fluid systems to prevent reverse flow. Whether for water, oil, steam, or air, choosing the right type of check valve ensures system efficiency and safety. This guide explores wafer type check valves, various non return valve types, pricing, and uses—all available at Udhhyog.

What is a Non Return Valve (NRV)?

A non return valve (NRV) or non return check valve allows fluid to flow in one direction only and automatically prevents backflow. These valves protect pumps, compressors, and pipelines from damage.

✅ Common Applications: ✔ Plumbing & water supply systems ✔ HVAC & fire protection systems ✔ Chemical & process industries ✔ Oil & gas pipelines

Non Return Valve Types

There are several types of NRVs, each designed for specific needs:

Swing Check Valve – A hinged disc swings to allow or block flow.

Lift Check Valve – The disc lifts with pressure and settles when flow reverses.

Ball Check Valve – A ball moves within the chamber to control direction.

Wafer Type Check Valve – Compact and space-saving, fits between flanges.

Dual Plate Check Valve – Two spring-loaded plates open/close based on flow direction.

👉 Udhhyog offers all major non return valve types with top-grade materials and precision design.

Wafer Type Check Valve – Compact & Efficient

A wafer type check valve is a slim, lightweight valve installed between pipeline flanges. It is ideal for space-constrained systems and high-performance industrial setups.

🔹 Advantages of Wafer Type Check Valves: ✔ Compact design, easy to install ✔ Minimal pressure drop ✔ Spring-assisted closure prevents water hammer ✔ Suitable for HVAC, power plants, and process industries

✅ Get the best wafer type check valves from Udhhyog – Trusted quality for industrial use!

Non Return Valve Price Range

Non return valve price depends on the material, size, and valve type. Below is a general price range (INR):Valve TypeMaterialPrice RangeSwing Check ValveCast Iron, SS₹500 – ₹5,000Lift Check ValveBronze, SS₹700 – ₹6,000Ball Check ValveBrass, PVC₹300 – ₹3,000Wafer Type Check ValveSS, Carbon Steel₹800 – ₹8,000Dual Plate Check ValveCast Steel, SS₹1,200 – ₹10,000

✅ Udhhyog provides competitive pricing on all non return valves – Quality at the right price!

Why Choose Udhhyog?

✔ ISO-certified quality ✔ Multiple valve types in all sizes ✔ Corrosion-resistant and durable ✔ Quick dispatch & trusted support

Conclusion

Whether you need a wafer type check valve for compact installations or want to compare non return valve types and prices, Udhhyog is your trusted supplier. With high-quality, durable options for every application, we ensure fluid control systems operate safely and efficiently.

🔹 Explore Udhhyog’s Non Return Check Valves Today – Industrial Grade. Dependable Performance.

#WaferTypeCheckValve#NonReturnValve#NonReturnCheckValve#CheckValveTypes#ValvePrice#IndustrialValves#FluidControl#Udhhyog

1 note

·

View note

Text

Wafer Type Check Valve & Non Return Valve Types & Price – Udhhyog

A check valve, also known as a non return valve, is critical in fluid systems to prevent reverse flow. Whether for water, oil, steam, or air, choosing the right type of check valve ensures system efficiency and safety. This guide explores wafer type check valves, various non return valve types, pricing, and uses—all available at Udhhyog.

What is a Non Return Valve (NRV)?

A non return valve (NRV) or non return check valve allows fluid to flow in one direction only and automatically prevents backflow. These valves protect pumps, compressors, and pipelines from damage.

✅ Common Applications: ✔ Plumbing & water supply systems ✔ HVAC & fire protection systems ✔ Chemical & process industries ✔ Oil & gas pipelines

Non Return Valve Types

There are several types of NRVs, each designed for specific needs:

Swing Check Valve – A hinged disc swings to allow or block flow.

Lift Check Valve – The disc lifts with pressure and settles when flow reverses.

Ball Check Valve – A ball moves within the chamber to control direction.

Wafer Type Check Valve – Compact and space-saving, fits between flanges.

Dual Plate Check Valve – Two spring-loaded plates open/close based on flow direction.

👉 Udhhyog offers all major non return valve types with top-grade materials and precision design.

Wafer Type Check Valve – Compact & Efficient

A wafer type check valve is a slim, lightweight valve installed between pipeline flanges. It is ideal for space-constrained systems and high-performance industrial setups.

🔹 Advantages of Wafer Type Check Valves: ✔ Compact design, easy to install ✔ Minimal pressure drop ✔ Spring-assisted closure prevents water hammer ✔ Suitable for HVAC, power plants, and process industries

✅ Get the best wafer type check valves from Udhhyog – Trusted quality for industrial use!

Non Return Valve Price Range

Non return valve price depends on the material, size, and valve type. Below is a general price range (INR):Valve TypeMaterialPrice RangeSwing Check ValveCast Iron, SS₹500 – ₹5,000Lift Check ValveBronze, SS₹700 – ₹6,000Ball Check ValveBrass, PVC₹300 – ₹3,000Wafer Type Check ValveSS, Carbon Steel₹800 – ₹8,000Dual Plate Check ValveCast Steel, SS₹1,200 – ₹10,000

✅ Udhhyog provides competitive pricing on all non return valves – Quality at the right price!

Why Choose Udhhyog?

✔ ISO-certified quality ✔ Multiple valve types in all sizes ✔ Corrosion-resistant and durable ✔ Quick dispatch & trusted support

Conclusion

Whether you need a wafer type check valve for compact installations or want to compare non return valve types and prices, Udhhyog is your trusted supplier. With high-quality, durable options for every application, we ensure fluid control systems operate safely and efficiently.

🔹 Explore Udhhyog’s Non Return Check Valves Today – Industrial Grade. Dependable Performance.

#WaferTypeCheckValve#NonReturnValve#NonReturnCheckValve#CheckValveTypes#ValvePrice#IndustrialValves#FluidControl#Udhhyog

1 note

·

View note

Text

Wafer Type Check Valve & Non Return Valve Types & Price – Udhhyog

A check valve, also known as a non return valve, is critical in fluid systems to prevent reverse flow. Whether for water, oil, steam, or air, choosing the right type of check valve ensures system efficiency and safety. This guide explores wafer type check valves, various non return valve types, pricing, and uses—all available at Udhhyog.

What is a Non Return Valve (NRV)?

A non return valve (NRV) or non return check valve allows fluid to flow in one direction only and automatically prevents backflow. These valves protect pumps, compressors, and pipelines from damage.

✅ Common Applications: ✔ Plumbing & water supply systems ✔ HVAC & fire protection systems ✔ Chemical & process industries ✔ Oil & gas pipelines

Non Return Valve Types

There are several types of NRVs, each designed for specific needs:

Swing Check Valve – A hinged disc swings to allow or block flow.

Lift Check Valve – The disc lifts with pressure and settles when flow reverses.

Ball Check Valve – A ball moves within the chamber to control direction.

Wafer Type Check Valve – Compact and space-saving, fits between flanges.

Dual Plate Check Valve – Two spring-loaded plates open/close based on flow direction.

👉 Udhhyog offers all major non return valve types with top-grade materials and precision design.

Wafer Type Check Valve – Compact & Efficient

A wafer type check valve is a slim, lightweight valve installed between pipeline flanges. It is ideal for space-constrained systems and high-performance industrial setups.

🔹 Advantages of Wafer Type Check Valves: ✔ Compact design, easy to install ✔ Minimal pressure drop ✔ Spring-assisted closure prevents water hammer ✔ Suitable for HVAC, power plants, and process industries

✅ Get the best wafer type check valves from Udhhyog – Trusted quality for industrial use!

Non Return Valve Price Range

Non return valve price depends on the material, size, and valve type. Below is a general price range (INR):Valve TypeMaterialPrice RangeSwing Check ValveCast Iron, SS₹500 – ₹5,000Lift Check ValveBronze, SS₹700 – ₹6,000Ball Check ValveBrass, PVC₹300 – ₹3,000Wafer Type Check ValveSS, Carbon Steel₹800 – ₹8,000Dual Plate Check ValveCast Steel, SS₹1,200 – ₹10,000

✅ Udhhyog provides competitive pricing on all non return valves – Quality at the right price!

Why Choose Udhhyog?

✔ ISO-certified quality ✔ Multiple valve types in all sizes ✔ Corrosion-resistant and durable ✔ Quick dispatch & trusted support

Conclusion

Whether you need a wafer type check valve for compact installations or want to compare non return valve types and prices, Udhhyog is your trusted supplier. With high-quality, durable options for every application, we ensure fluid control systems operate safely and efficiently.

🔹 Explore Udhhyog’s Non Return Check Valves Today – Industrial Grade. Dependable Performance.

#WaferTypeCheckValve#NonReturnValve#NonReturnCheckValve#CheckValveTypes#ValvePrice#IndustrialValves#FluidControl#Udhhyog

0 notes